NO-TAC 8000

The NO-TAC 8000 ® is a new technology designed to reduce or eliminate stickies and pitch, generated from the milling process of recycled and virgin fibers. This solution is composed of synthetic and natural polymers which penetrate the various contaminants and neutralizes their adhesive properties. This unique technology is based on the principle of “de-tackifying” and eliminating the adhesive or “TAC” effect.

The NO-TAC 8000 ® transforms the adhesive nature of the contaminants and collects the accumulated macro stickies, which are removed by the cleaning systems of the paper machiine. The remaining micro stickies are physically changed into an inert, non tacky particle substance, which cannot stick to machine parts causing machine runnability issues.

What are contaminants?

Contaminants are organic and inorganic substances contained within the raw materials used to produce paper.

Pitch is a natural and colloidal contaminant resulting from the transformation of wood extractives due to variations in temperature and Ph in pulp production. The primary component in pitch formation is wood resins, which is used by trees to heal itself from injury.

Stickies derive from hot melts, inks, glues, waxes, tapes and other adhesive materials contained within the recycled raw material used to produce secondary paper. These impurities agglomerate to form larger particles, creating issues in the wet end, dry end, size press, rewinder and conversion.

Evaluation Method

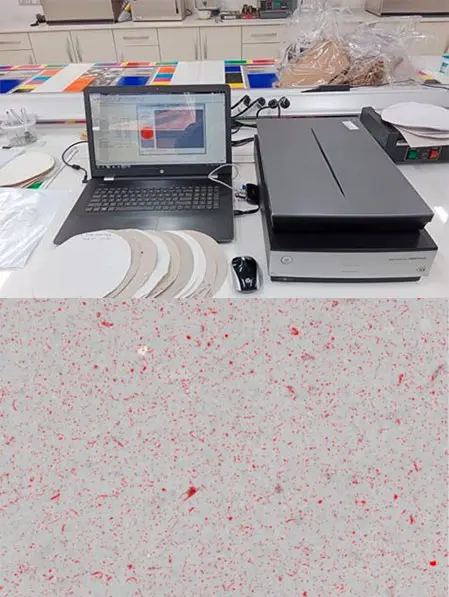

SPECKCHECK 2 Software

The SpeckCheck 2 software combines with the latest scanning technology designed to measure and count the contaminant particles present in the paper.

SpeckCheck 2 uses image processing algorithms accurately detecting and classifying each particle according to its reflectance in the light of the scanner. They will then be designated according to their diameter, width, length and equivalent black area.

The SpeckCheck 2 software complies with TAPPI methods T213, T277, T437 and T563, providing the customer confidence in the use of this sophisticated evaluation tool.

Why contaminant control

The paper industry is growing worldwide, and paper manufacturers are confronted with continued deterioration in the quality of furnish and the difficult to process compounds they contain. Suntex realized the opportunity to develop and commercialize specific market leading chemistry which provides a real solution to combat the organic and inorganic contaminants in virgin and recycle paper processes.